compressive strength tests|compressive strength test standard : broker The compressive strength test has multiple objectives, including: To assess the quality of concrete in relation to the specifications for a particular project. To gauge the potential load-bearing capacity of a concrete . WEBFaixa Ganhadores Valor; 15 acertos 1 R$ 1.749.899,97 14 acertos 192 R$ 1.911,01 13 acertos

{plog:ftitle_list}

21 de set. de 2018 · 12. In-Game. This is a 2D crafting survival sandbox game. You will be able to explore a huge 2D side-view world, building houses, crafting tools, weapons and armour from the resources you collect. There is a day/night cycle and each night many dangerous monsters can be found and defeated.

Compressive strength of concrete depends on many factors such as water-cement ratio, cement strength, quality of concrete material, quality control during the production of concrete, etc. Test for compressive strength is carried out .For designers, compressive strength is one of the most important engineering properties of concrete. It is standard industrial practice that the compressive strength of a given concrete mix is classified by grade. Cubic or cylindrical samples of concrete are tested under a compression testing machine to measure this value. Test requirements vary by country based on their differin. Compressive strength testing of concrete:-The test is carried out using 150mm concrete cubes on a Universal testing machine or compressive testing machine. Apparatus. As per IS: 516-1959 Compressive testing machine (2000Kn),15cm×15cm×15cm steel cube molds or Cylinder having Dia 15cm and length 30cm are used. The compressive strength test has multiple objectives, including: To assess the quality of concrete in relation to the specifications for a particular project. To gauge the potential load-bearing capacity of a concrete .

Procedure: Compressive Strength Test of Concrete Cubes. For cube test two types of specimens either cubes of 15cm X 15cm X 15cm or 10cm X 10cm x 10cm depending upon the size of aggregate are used. For most of the works cubical .sented by compressive strength tests on mortar cubes compacted by means of standard vibration machine. 2. SAMPLING AND SELECTION OF TEST SPECIMEN 2.1 The samples of the cement shall be taken in accordance with the requirements of IS: 3535 1986* and the relevant standard specification for the type of cement being tested. The representa Significance of Compressive Strength Testing. The compressive strength of concrete is akin to the heartbeat of a building. It verifies concrete’s ability to withstand significant forces and sustain loads without failure, ensuring the .High-strength PCC (usually defined as PCC with a compressive strength of at least 41.37 MPa (6000 psi)) has been designed for compressive strengths of over 137.90 MPa (20,000 psi) for use in building applications. Test Procedures. The standard compression tests are: AASHTO T 22 and ASTM C 39: Compressive Strength of Cylindrical Concrete Specimens

concrete strength test results. Procedures described are applicable to the compressive strength test results required by ACI 301, ACI 318, and similar specifications and codes. Statistical concepts described are applicable for the analysis of other common concrete test results, including flexuralNon-destructive tests of concrete is a method to obtain the compressive strength and other properties of concrete from the existing structures. This test provides immediate results and actual strength and properties of concrete structure. The .Compressive strength is an essential property in structural materials, for example, mortar, which comprises the interacial transtition zone in concrete, stone, and steel, since material design is normally evaluated in terms of the risk of compression failure. In addition the CBM is known as having strength for compression force. Therefore plenty of standard tests exist to measure .

Compressive strength is a critical parameter in evaluating the mechanical performance of concrete, serving as a metric of its ability to withstand loads and stresses. Governed by standard C 39/C 39M, compressive strength tests are instrumental in assessing concrete's suitability for various construction applications. Test Methodology Scope Similarly, when using the maturity method on your jobsite to test compressive strength, it is recommended to perform cylinder break tests on day-28 of your concrete’s lifecycle for acceptance . These fundamental parameters include the elastic limit, which for "Hookean" materials is approximately equal to the proportional limit, and also known as yield point or yield strength, Young's Modulus (these, although mostly associated with tensile testing, may have compressive analogs) and compressive strength.

The compressive strength test is among the most dependable and hands-on tests done on concrete to assess its performance. Overall, the compressive strength test provides information regarding numerous properties of concrete. The quality of concrete can be simply determined when the compressive strength is identified.Every arithmetic average of any three consecutive strength tests equals or exceeds the specified compressive strength. No strength test falls below the specified compressive strength by more than 500 psi (3.5 MPa) if the specified compressive strength is 5000 psi (35 MPa) or less; or by more than 10 percent of the specified compressive strength .Table 2. Mean tensile strength and compressive strength for selected sedimentary rock types (after Johnson and Degraff, 1988). The behavior of intact rock in the post-peak dom ain is not a true rock property and is partially dependent on the stiffness of the loading system. A testing machine consists of an assembly of A compression testing machine, often referred to as a compressive strength testing machine, is an essential apparatus used to determine the compressive strength of materials, particularly concrete and .

compressive strength test standard

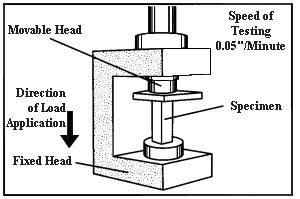

core compressive strength test results. Factors that affect in-place concrete strength are reviewed so sampling locati ons that are consistent with objectives of the investigation can be selected. Strength correction factors are presented for converting the measured strength of non-standard core-test specimens to the strength of equivalent . The test involves preparing test specimens of concrete cubes with even maximum load distribution before compression testing to determine the compressive strength of concrete. Factors such as water and cement ratio, aggregate type, and curing conditions affect the compressive strength of a material or commercial and industrial structures. This process, known as compression strength testing, though seemingly simple, is vital in ensuring the strength and durability of numerous materials we rely upon daily. Purpose of Compressive Test. Materials undergo compression testing much like athletes pushing their bodies to the limit in an intense workout session. This process assesses the .A compression testing machine is a universal testing machine (UTM) specially configured to determine a material’s strength and deformation behavior under compressive (pressing) load. A typical machine for compression tests consists of a load cell, a crosshead(s), compression test tools, electronics, and a drive system.It is controlled by testing software used to define .

For example, ASTM C39, a standard for testing the compressive strength of concrete, specifies a cylinder that is 12 inches (305 mm) in height and 6 inches (152 mm) in diameter. It’s crucial to prepare and measure the specimen accurately to ensure reliable test results. Any flaws in the specimen, such as cracks or surface irregularities, can .

Compression testing determines important parameters such as compressive yield strength, ultimate compressive strength, and modulus of elasticity. Engineers then use this data to ensure that components used in compression applications, such as bridges or columns, can withstand the required stress levels without cracking or deforming.

Compression testing is a very common testing method that is used to establish the compressive force or crush resistance of a material and the ability of the material to recover after a specified compressive force is applied and even held over a defined period of time. This article will shed light on compression testing and the significance of flexural modulus in assessing material strength. Compression Testing. Compression testing involves subjecting a material to compressive forces until it deforms or fails. A sample is placed between an upper and lower fixture, such as parallel compression plates or .

5.1 Care must be exercised in the interpretation of the significance of compressive strength determinations by this test method since strength is not a fundamental or intrinsic property of concrete made from given materials. Values obtained will depend on the size and shape of the specimen, batching, mixing procedures, the methods of sampling, molding, . Compressive strength is a fundamental parameter that informs the safety, quality and durability of a particular mix of concrete. Testing according to ASTM C39 is central to the QA/QC process. For over 80 years, ASTM C39 has been the industry standard test method for testing the compressive strength of concrete cylinder specimens. In this .

The modified CSS was analyzed in terms of particle size and (Toxicity Characteristic Leaching Procedure) TCLP testing, while cement mortar specimens were subjected to a battery of tests including compressive strength, Freeze-thaw experiment, TCLP testing and cement stability testing.

with lawn mower compression test

compressive strength test procedure

WEB21 de fev. de 2024 · download eng original | ptbr e esp traduzido por: senseidc (fapfapgames) obs: a versÃo android É um port de pc, pode haver bugs, recomendo .

compressive strength tests|compressive strength test standard